Social Responsibility Report and Publicity

Release time:

2023-10-30

Source:

Social Responsibility Report and Publicity

Hunan Changle Building Materials Co., Ltd

Social Responsibility Report

- corporate governance system

Good corporate governance is the internal driving force for enterprises to achieve sustainable development. Since the establishment of the company in 2016, the company has organically combined corporate governance with production and operation. In strict accordance with the requirements of the Company Law and relevant national laws, regulations and rules, we should establish a modern enterprise system, improve the corporate governance structure and standardize the operation of the company. Establish a systematic and scientific regulatory system based on the Articles of Association, with the rules of procedure of the general meeting of shareholders, the rules of procedure of the board of directors, the rules of procedure of the board of supervisors, and the working rules of the general manager as the main structure. It has formed a mechanism of checks and balances on the rights of decision-making, implementation, operation and management, and effective supervision with the general meeting of shareholders, the board of directors, the board of supervisors and the management as the main body, ensuring the healthy operation of the company's production and operation and other business activities, and realizing the sustainable and healthy development of the company.

2. company development

In 2022, the company will focus on the main body of reform and innovation, thoroughly implement the party's 19th National Congress of the Communist Party of China in the new era of socialism with Chinese characteristics, innovate marketing strategies, actively respond to market changes, carry out independent innovation, pay attention to financial budget and cost assessment, and strengthen the company's defense and control The ability to control risks has promoted the sustained and rapid growth of the company's operating performance. Changle Building Materials Co., Ltd. realized sales income of 70 million yuan and paid taxes of 4 million yuan.

3. Product Management

As a rookie in the light-weight board industry, the company has set up a factory in Xiangtan Tianyi Economic Development Zone to vigorously develop new green and environmentally friendly building materials around the requirements of the "two-type enterprise" construction standard, independently research and develop "two-type" products and promote "two-type" technologies. The products make extensive use of the technical process of recycling purchased solid waste to prepare high-quality board products. At present, the independently developed high-strength, environmental protection and energy-saving calcium silicate board has been included in Hunan 100 key new products; realize resource conservation and recycling; by strengthening the awareness of environmental protection of all employees, deeply tapping the potential of energy saving and consumption reduction, implementing the construction of environmental protection facilities, and building a "two-type" corporate culture, the company takes high-end environmental protection plate technology as its research and development goal, and is committed to the research and development of energy-saving and environmental protection new building materials products with its own intellectual property rights, committed to the innovation and application of new products, new processes, new technologies, and new materials, committed to the introduction and re-innovation of new technologies and new processes for energy conservation and emission reduction, clean production, and initially formed a highly operational "two-type" Enterprise construction model. Compared with other enterprises in the industry, the company has great advantages in product quality, production energy consumption, operation and management, pollutant discharge and so on, and has obvious two-type demonstration benefits.

4. environmental protection

The company takes environmental protection as an important part of the enterprise's sustainable development strategy, pays attention to fulfilling the responsibility of environmental protection, and actively practices environment-friendly and resource-saving development.

The environmental management into the enterprise management system, in-depth production of all aspects. First of all, the company strengthens publicity in various departments to improve the environmental protection awareness of all employees. Secondly, implement environmental management indicators in every link in the product production process, establish a target responsibility system from the top and middle levels of the company to the grassroots level of the team, form a management network, timely report the production and pollution discharge of various departments, and achieve responsibilities in place, rewards and punishments. Clear, truly penetrate environmental protection and environmental concepts into the hearts of every employee.

The use of modern information technology means, the implementation of paperless office, the promotion of conservation-oriented society. Companies actively introduce financial computerization, ERP management, intranet and other modern information technology means. Constantly improving the OA office system not only saves paper consumption, communication costs and mailing costs, but also reduces the use of telephone, fax and mail contact information on social communication lines and postal resources. Actively promote the construction of a conservation-oriented society.

In addition, the company also encourages employees to innovate technology, eliminate backward production processes, and build environmentally friendly enterprises. The production system collects rationalization suggestions around the theme of "energy saving and cost reduction, production increase and efficiency increase", which fully improves the comprehensive utilization rate of energy and machinery and materials. It puts forward rationalization suggestions on innovation and improvement including equipment, pipeline lines, waste equipment and facilities, machinery and materials, waste energy, etc. to reduce the consumption of water, electricity, gas and other energy sources and recycle resources, and puts forward optimization and improvement on the existing production process, in order to achieve energy conservation and emission reduction, increase production and efficiency.

Hunan Changle Building Materials Co., Ltd

10 July 2023

Carbon footprint verification report and publicity

Greenhouse gas accounting report and publicity

Hunan Changle Building Materials Co., Ltd

Greenhouse gas emission report

Report Subject (Seal): Hunan Changle Building Materials Co., Ltd.

Report year: 2022

Report Date: September 05, 2023

- Preparation basis

According to the Guidelines for Accounting Methods and Reporting of Greenhouse Gas Emissions of Enterprises in Other Industries (for Trial Implementation) issued by the National Development and Reform Commission, the enterprise has calculated the greenhouse gas emissions in 2022 and filled in the relevant data forms. The relevant information is now reported as follows:

- Basic information of the reporting body

Introduction of basic information of 2.1 enterprises

Hunan Changle Building Materials Co., Ltd. was established in March 2016. Its legal representative is Chen Hui, located at 306 Yingwu Road, Yisuhe Town, Xiangtan County. It is a high-tech enterprise specializing in the research and production of calcium silicate board, fiber cement flat plate and other products and providing overall solutions for the board. Up to now, it has a total assets of 0.12 billion yuan, covers an area of 40000 square meters and employs 135 people. With an annual production capacity of 20 million square meters of calcium silicate board and fiber cement flat plates; built plate industry perfect testing facilities. The company has passed the quality management system, environmental management system, occupational health management system certification. Products have been identified as new wall material products.

As a rookie in the light board industry, the company has set up a factory in Xiangtan Tianyi Economic Development Zone to vigorously develop new green and environmental protection building materials and independently develop calcium silicate board and fiber cement products around the requirements of "environmental protection and energy saving" construction standards. At present, the self-developed high-strength environmental protection and energy-saving calcium silicate board has been included in Hunan's 100 key new product promotion plans; realize resource conservation and recycling; the company takes high-end environmental protection plate technology as the research and development goal, devotes itself to the research and development of energy-saving and environmental protection new building materials with its own intellectual property rights, and devotes itself to the innovation and application of new products, new processes, new technologies, and new materials., Committed to the introduction and re-innovation practice of new technologies and new processes of energy conservation and emission reduction, clean production, compared with other companies in the industry, the company has great advantages in product quality, production energy consumption, operation and management, pollutant emission and so on.

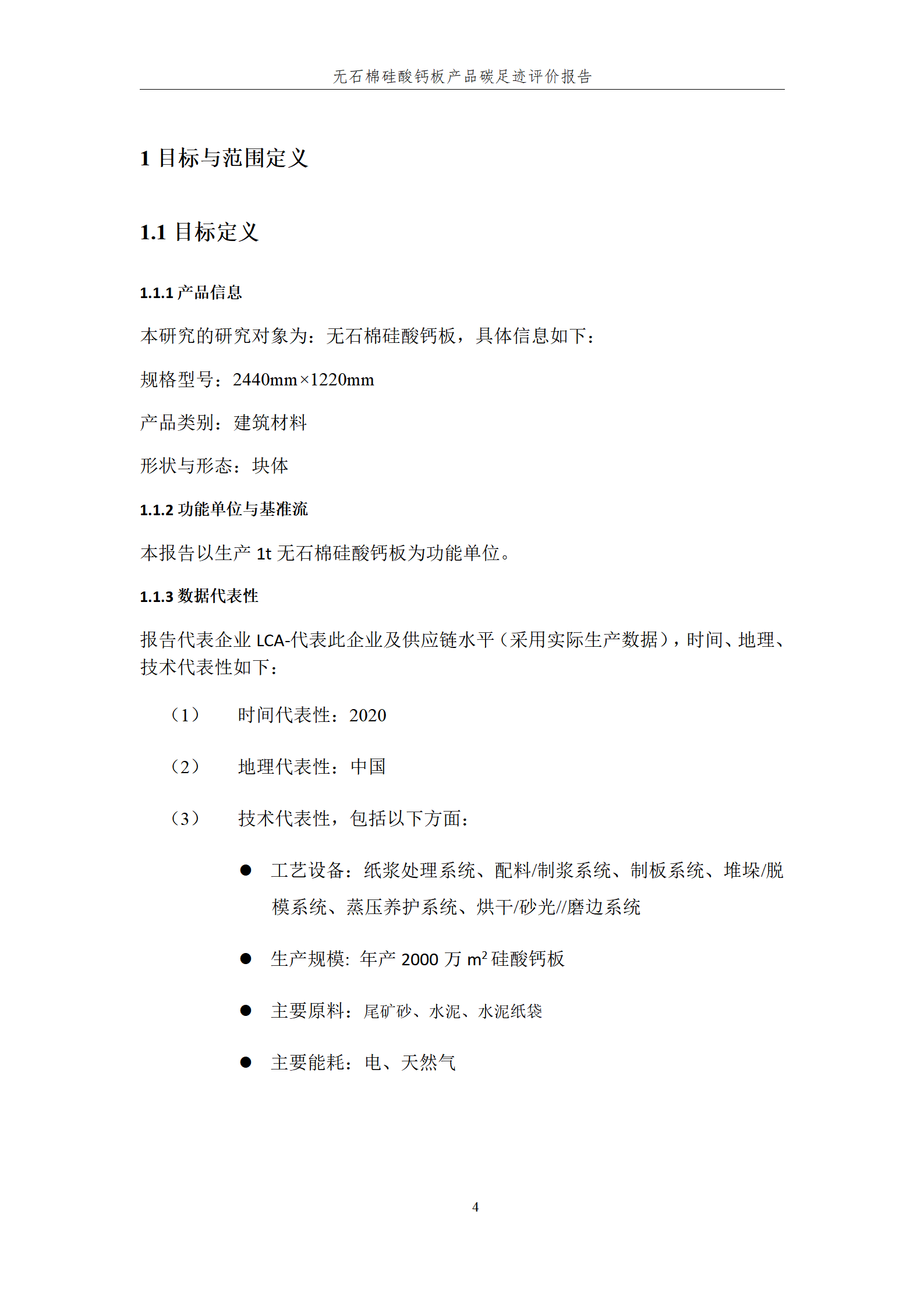

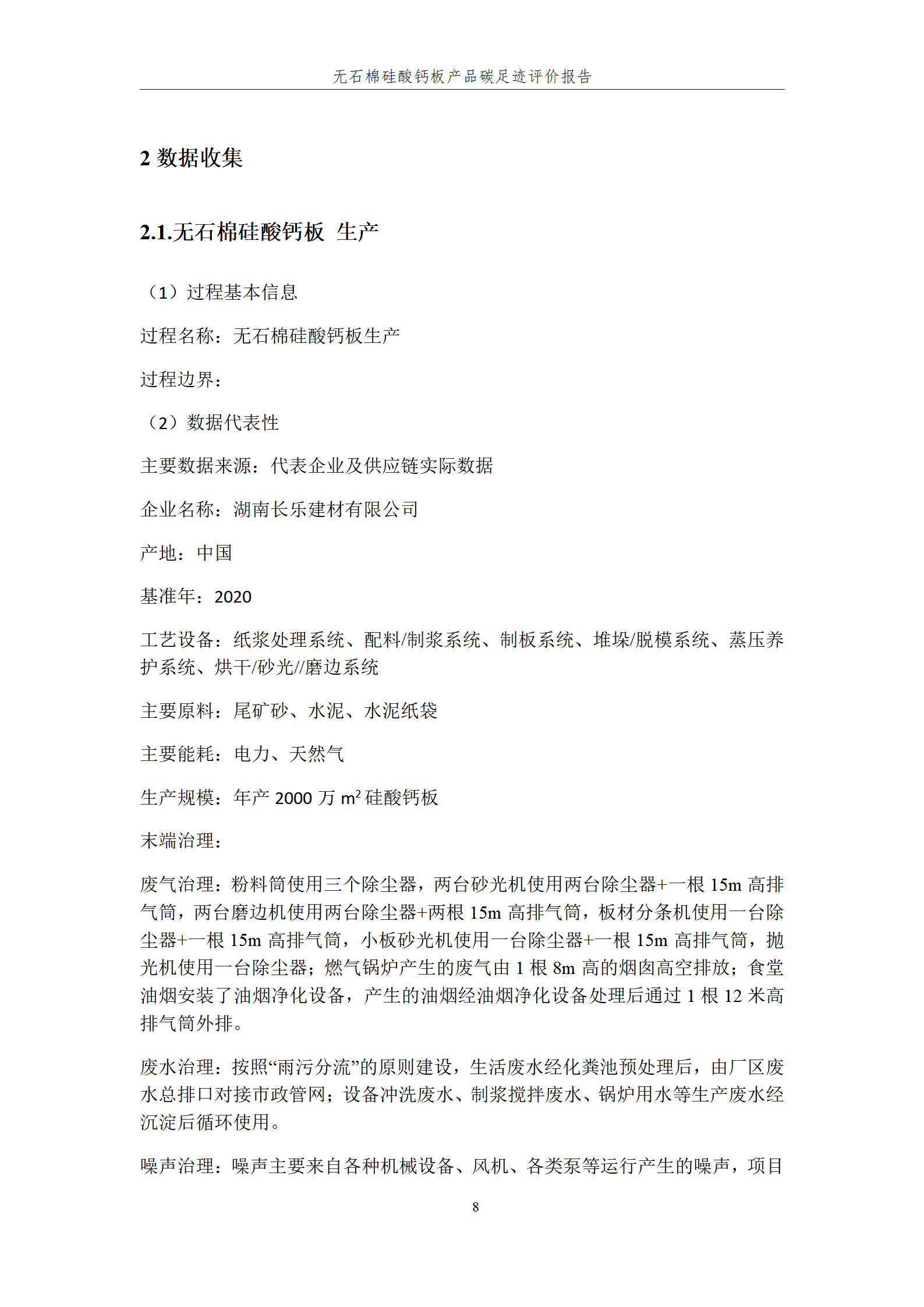

Brief Introduction of 2.2 Production Process

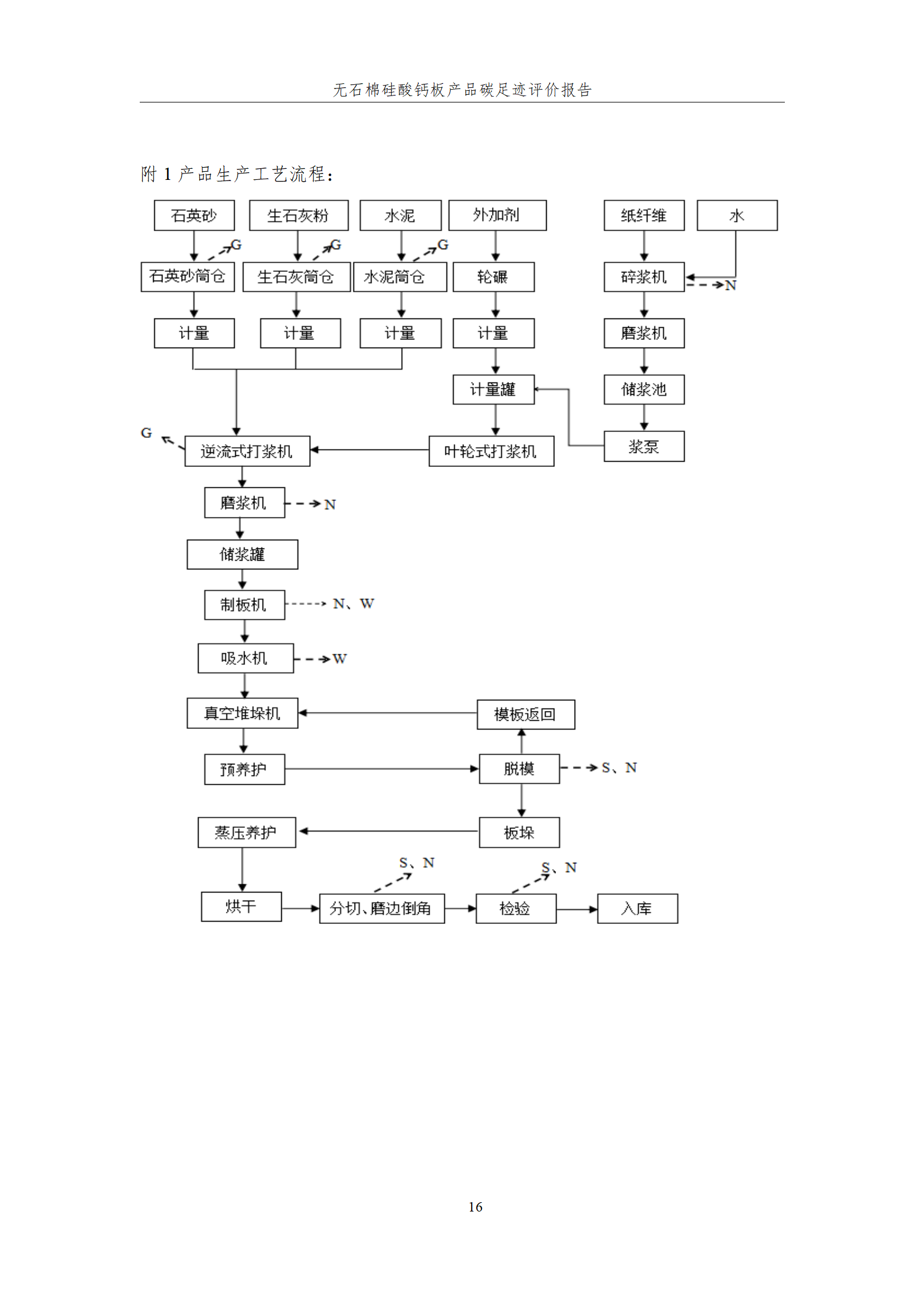

1) Production process flow and discharge node diagram

Production process flow chart

2) Process flow description

(1) Raw material preparation

The main tailings sand, quicklime, cement, cement paper bags, other fillers and admixtures and other raw materials are mixed and stirred to make a certain concentration of slurry, and quantitatively supplied to the host-copy method plate making machine.

The purchased paper fibers are added into the pulper after metering, and the quantitative water is added to loosen fully, and the loosing time of each pot material is 40-60 minutes. The loosened pulp is pumped into the slurry tank, and then diluted with water to a lower concentration (4-6%) into the double-disc refiner for thinning and grinding to improve the beating degree of the pulp. The milled pulp is pumped into the slurry storage tank and then metered into the impeller beater using a metering tank. After being measured, the filler and admixture are fed into the impeller-type beater and the pulp is evenly beaten and then fed into the counterflow-type beater. The tailings sand, quicklime, cement, etc. are directly sent to the counterflow beater after metering.

All the measured raw materials are put into the counterflow pulper for stirring and mixing. The mixed slurry is stored by the bucket type pulping machine and supplied to the single disc pulping machine quantitatively and evenly by the pump. The slurry is uniformly ground by the pulping machine to further mix the slurry. The ground slurry enters the slurry storage tank and is stirred, and is uniformly and continuously supplied to the plate making machine for use.

(2) Plate making section

The board making process of the product is the main link in the production process. In this project, the production line host equipment uses the copy method plate making machine.

The raw material preparation section continuously supplies materials to the plate making machine. After the slurry enters the net cage, the material layer is formed on the net wheel through the internal and external pressure difference of the net wheel and transferred to the endless wool cloth. The wool cloth holds the material layer around the chest roller and contacts the forming cylinder. At this time, the forming cylinder, the material layer, the wool cloth and the chest roller are in close contact. When the wool cloth is gradually separated from the forming cylinder, the material layer is in close contact with the forming cylinder to form a vacuum negative pressure, so that the material layer is evenly separated from the wool cloth and adsorbed on the forming cylinder. This continuous extrusion winding into a certain thickness structure uniform dense billet. After multi-layer winding to reach the set blank thickness, PLC controls the forming cylinder to automatically cut off the blank. The expanded blank is transported by the blank receiving belt, passed through the longitudinal cutting device to the positioning belt and reached the transverse cutting and stacking station. The plate making machine adopts a Ø1900mm large-diameter forming cylinder, and two 2400mm slabs can be formed after one-time vertical and horizontal cutting. The slabs after cutting are stacked by a stacker, and one template and one slab are stacked alternately. This one-die-one-plate production process can fully ensure the flatness of the slab.

(3) Pressurization and pre-maintenance section

After the stacking is completed, the plate stack is transported to the press by the crane for pressurization. The pressurized plate stack is transported to the pre-curing kiln by truck. The slab needs to be pre-cured for a period of time to achieve the initial strength of the slab to facilitate mechanical demoulding and stacking. Pre-curing with pre-curing kiln, the general temperature is maintained at 50~70 ℃,4h ~ 5h can be out of the kiln. Pre-curing kiln wall set heat pipe, rely on steam to provide heat source. The pre-cured slab is sent to the demoulding machine, which completes the demoulding and stacking work and timely adds the steam curing backing plate. The removed formwork is piled up on the trolley after being cleaned and brushed by the dust cleaning and oil brushing machine, and then returned to the stacker along the track for recycling. The slab is then marshalled into the autoclave before being ferried to the autoclave by car ferry.

(4) Autoclaved curing

After the slab is demoulded, the plate stack on the steam curing trolley is pulled by the winch into the autoclave for autoclave curing. Under high temperature and high pressure, the silica, calcium hydroxide and water in the slab undergo hydration reaction, and finally form tobermorite and some xonotlite crystals. After the slab enters the autoclave, it needs to be treated at high temperature and autoclaved for about 18 hours. The general autoclaving system is 4 hours of heating, 10 hours of constant temperature, 4 hours of cooling, and the constant pressure is 1.0MPa. Generally, it is necessary to vacuum the kettle before autoclaving, for about 30 minutes, to -0.5 atmospheres. This is more conducive to the heat absorption of the plate evenly, not to cause steam curing defects.

(5) Demoulding and drying section

The steamed slab should be dried to make the water content of the slab below 10%, so as to better meet the requirements of the construction industry. In this project, comb dryer is selected, and the slab is continuously dried in the tunnel kiln by the chain plate driving the comb. The drying heat source is provided by the boiler in the factory area, and the hot air is circulated in the kiln through the heat exchanger and the axial flow fan, so that the slab is evenly dried. The plate stacking trolley with steam curing backing plate coming out of the autoclave is ferried to the drying section by car ferry, and the plate and steam curing backing plate are separated after demoulding. The steaming pad is sent back to the demoulding section along the track for recycling, and the plate is sent to the dryer by the plate roller conveyor for drying. The plates dried by the dryer are stacked and then sent to the semi-finished product storage area by the forklift.

(6) Sanding and edging chamfering section

In order to ensure the smooth surface of the board and improve the appearance quality, the dried slab needs to be cut by a single-sided sander. The sanded board is then ground and chamfered by the edge grinding and chamfering unit to meet the requirements of the construction industry on the appearance and size accuracy of the board and the joint between the board. After appearance inspection and sample sampling inspection, the sanded and edged plates are sent to the finished product warehouse for storage by forklift.

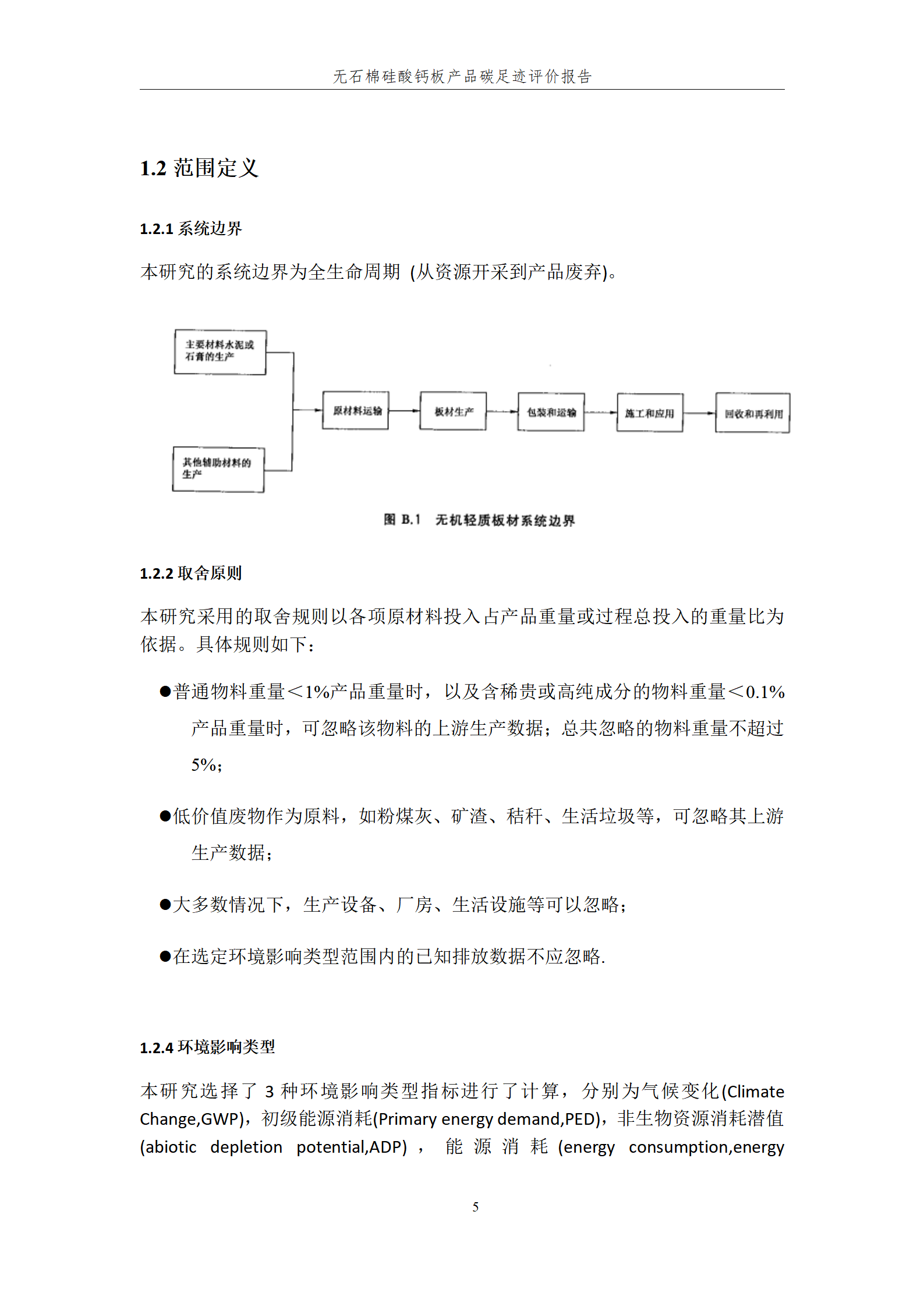

- Accounting Boundary Division and Emission Source Identification

Accounting boundary division:Including the entire enterprise production and living area production of greenhouse gases.

Emission source identification:The plant does not produce greenhouse gases in the production process. The main sources of greenhouse gases in the plant are the use of electricity and natural gas, which are purchased energy. Electricity is purchased from the social power grid for production lines, public equipment, lighting, living and office facilities; natural gas is purchased from the gas pipeline network and used as a heat source for heating.

- greenhouse gas emissions

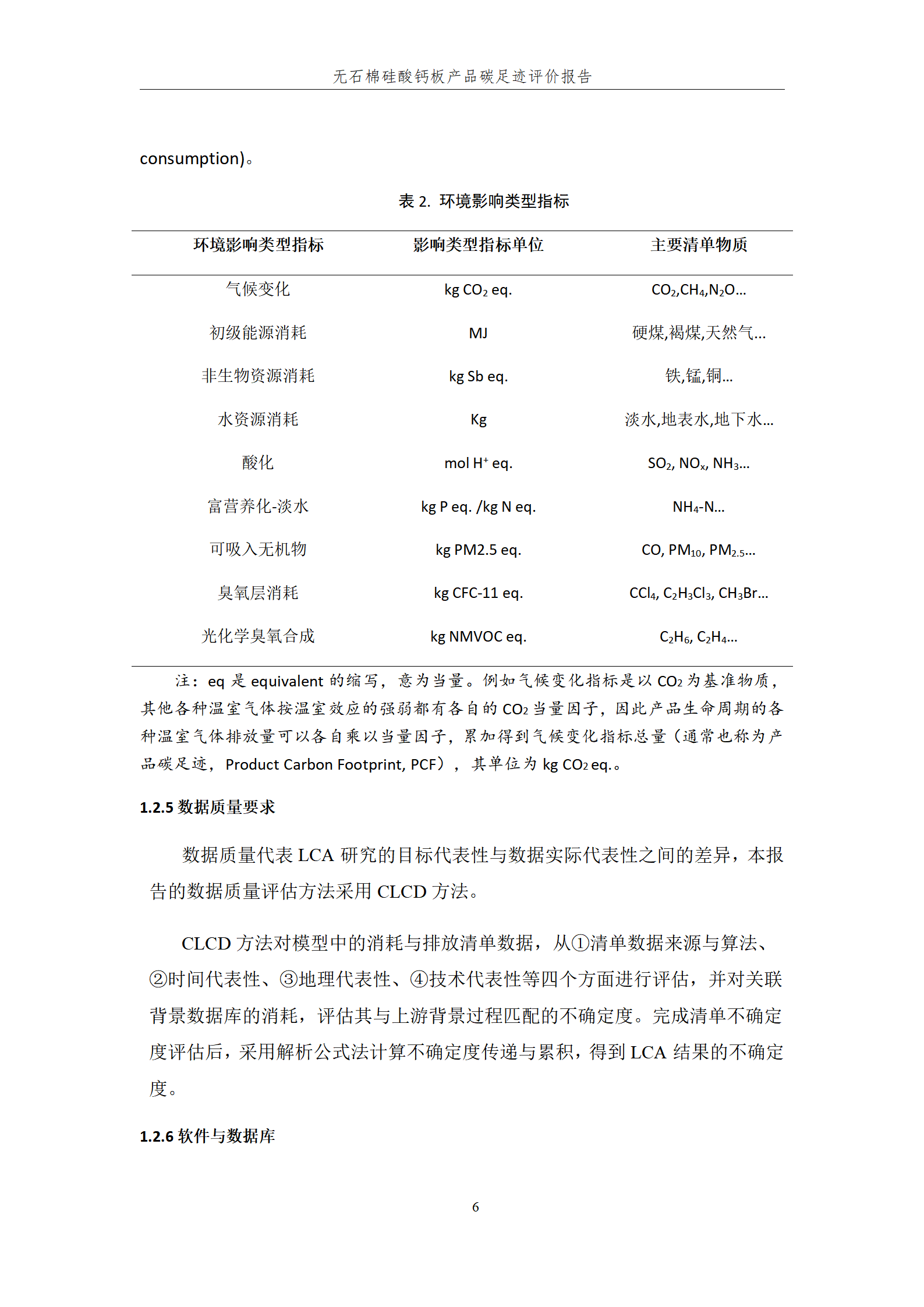

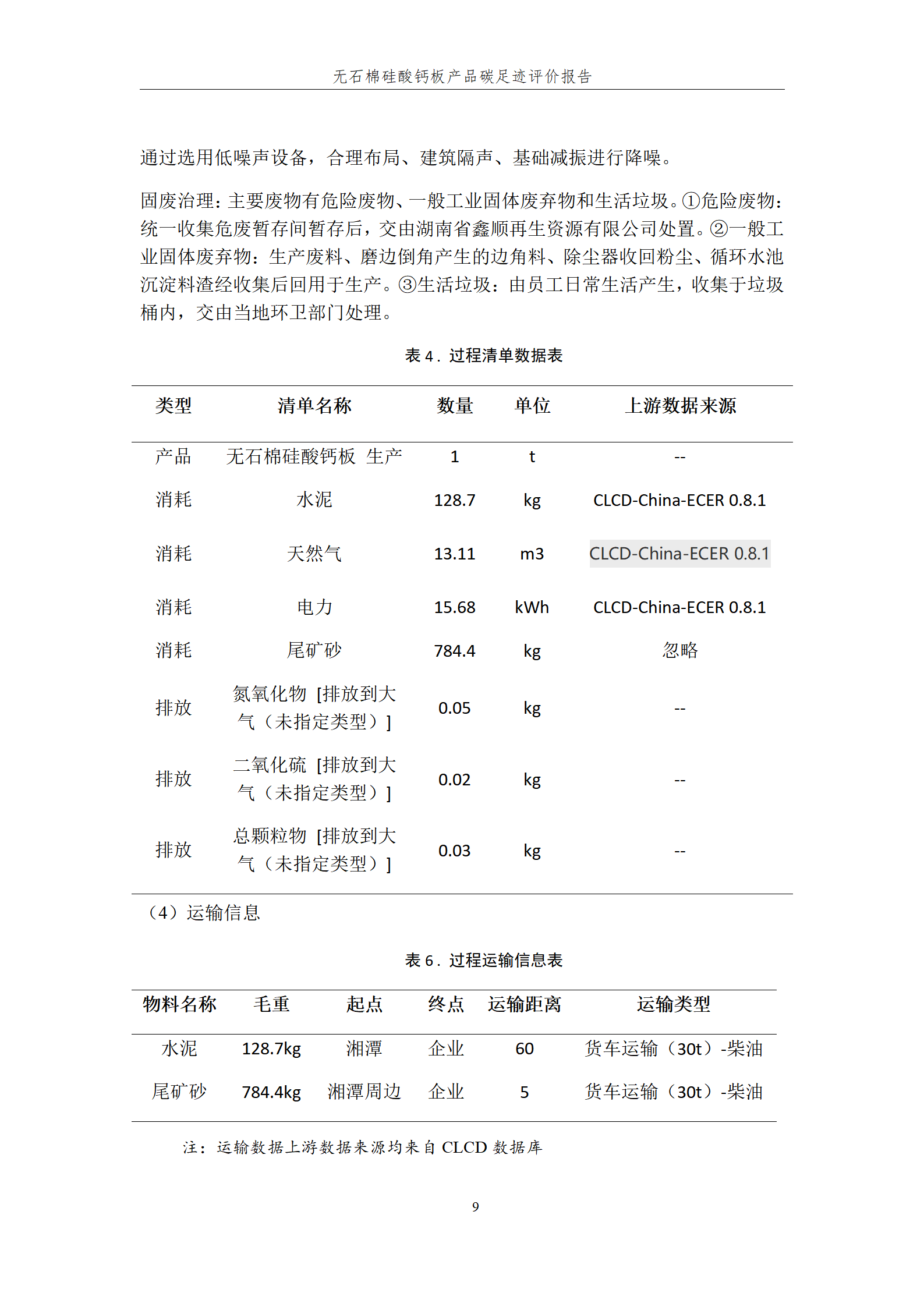

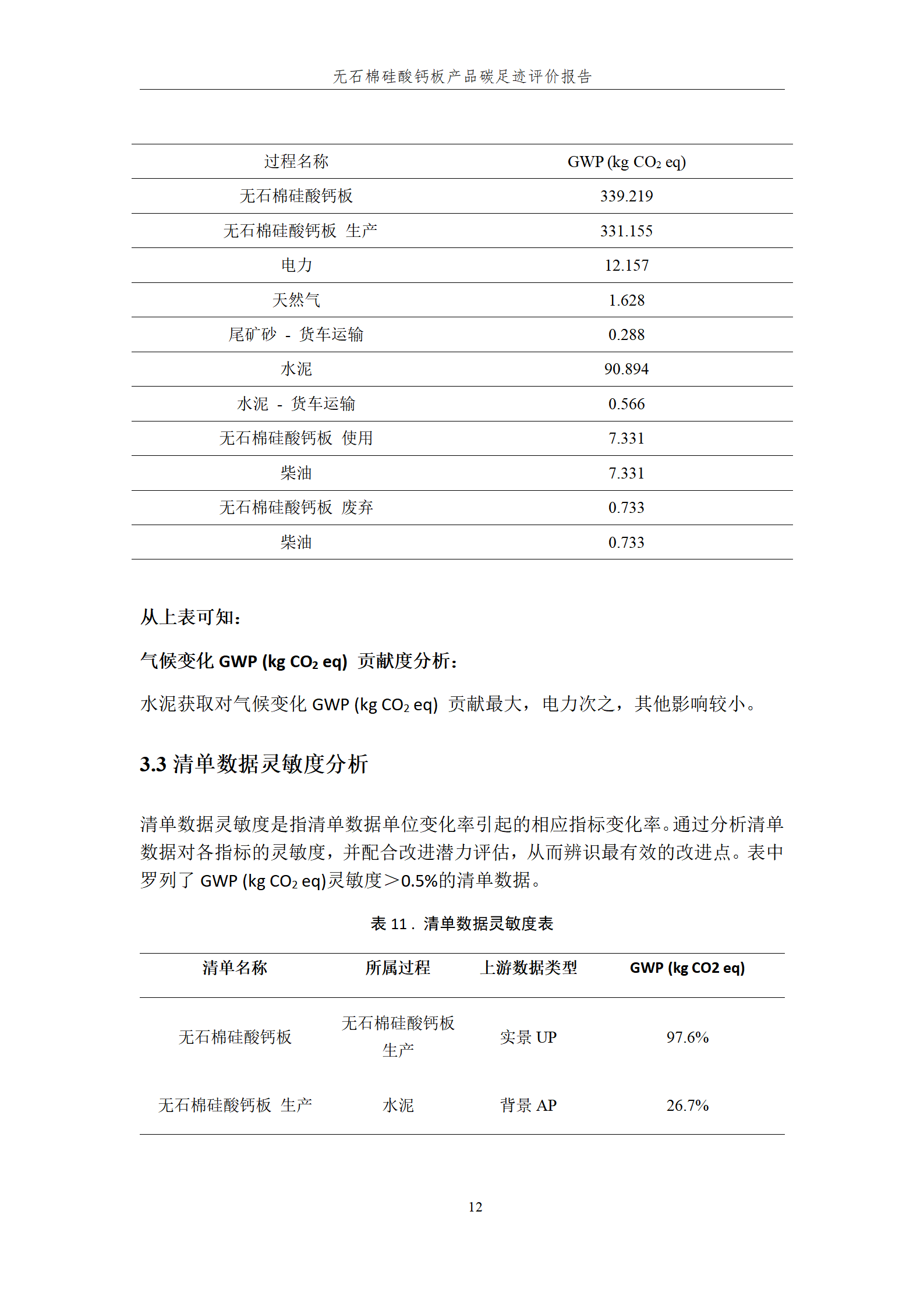

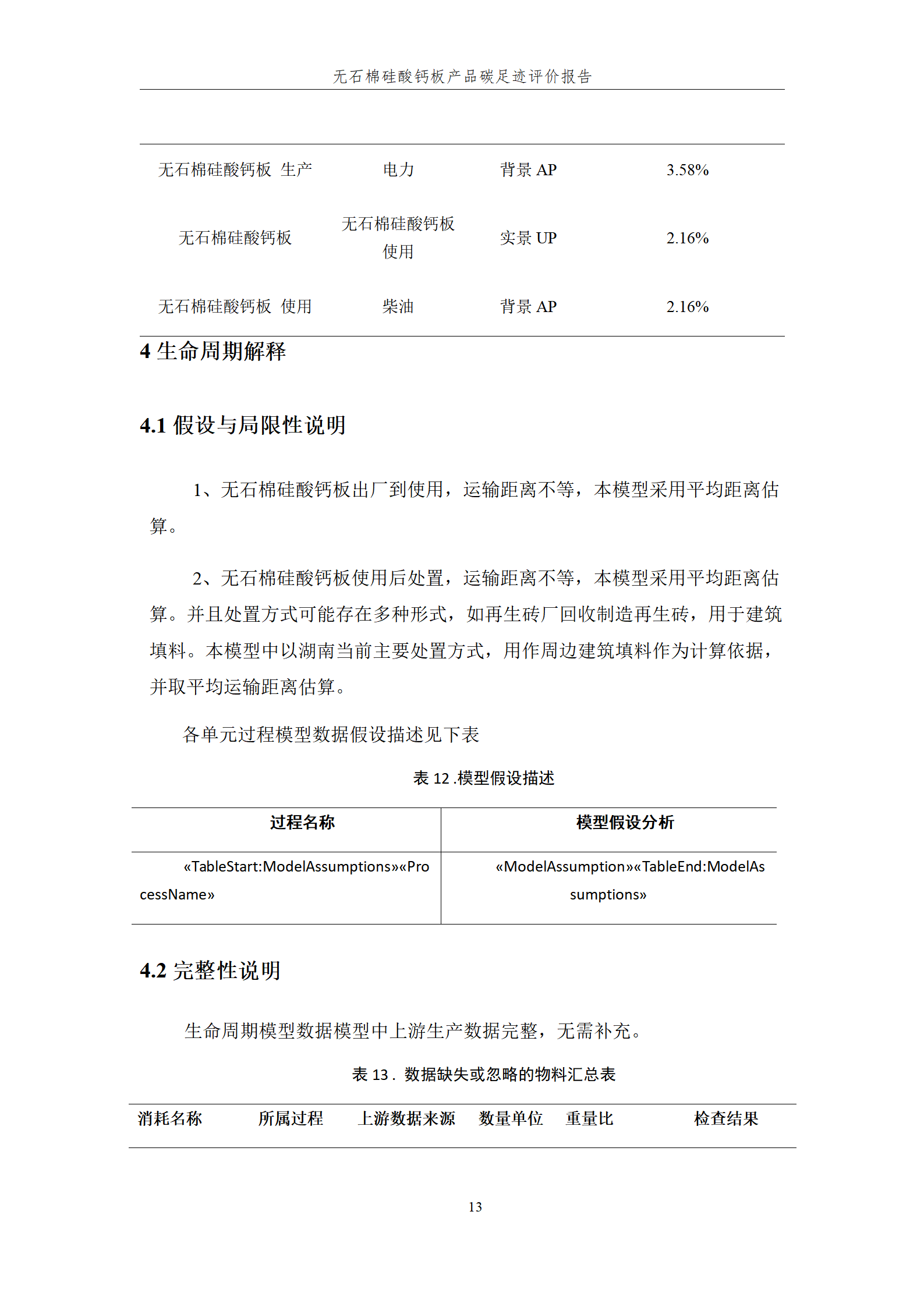

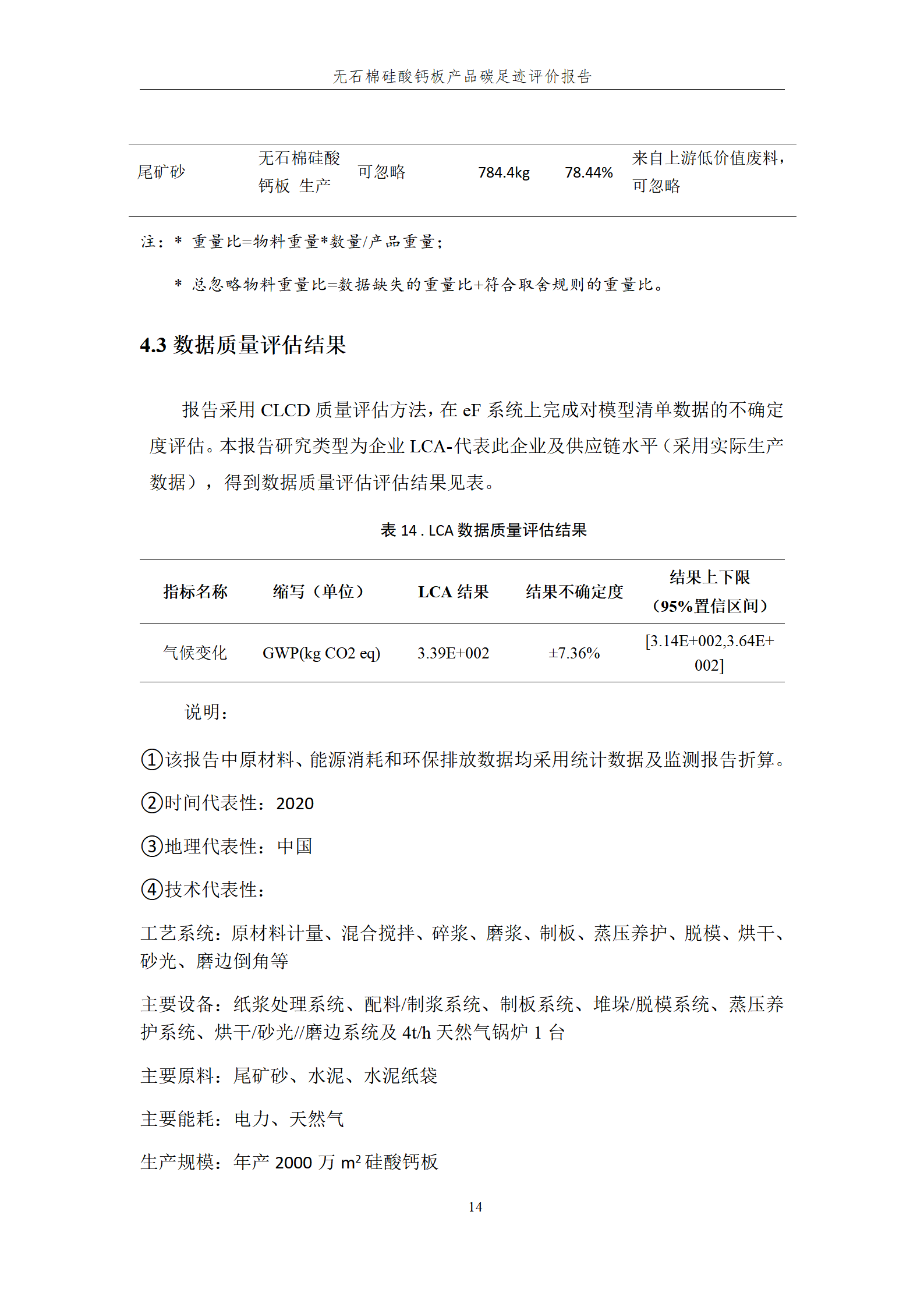

Table 1 Report on Greenhouse Gas Emissions to 2022

|

Category |

Quantity (tCO2) |

|

Total carbon dioxide emissions of enterprises |

6007.99 |

|

emissions from fossil energy combustion |

1986.78 |

|

Emissions corresponding to purchased electricity |

4021.21 |

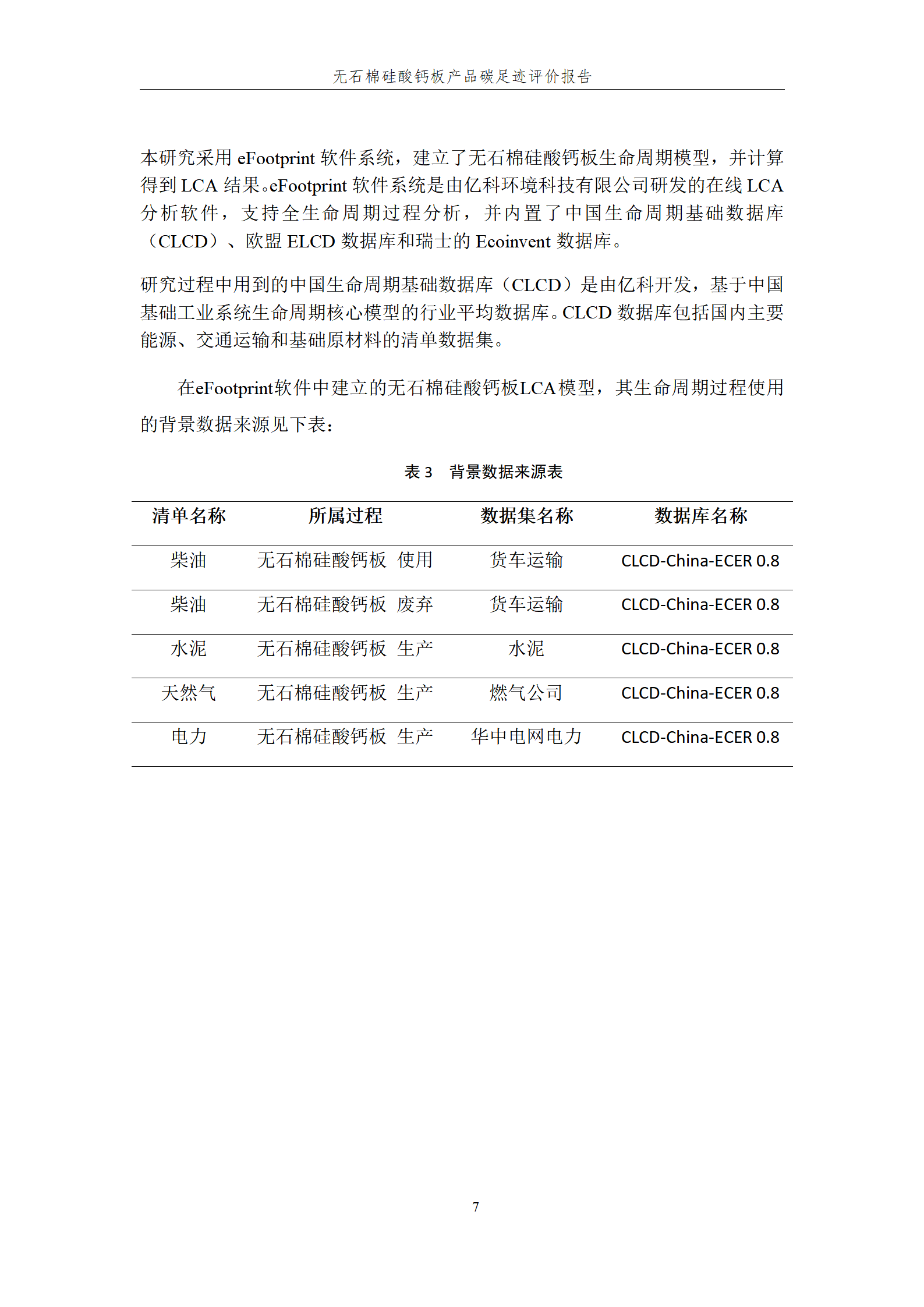

- Activity level and emission factor data sources

Activity level data are derived from energy consumption monthly settlement vouchers.

Table 2 Activity Level Data Sheet

|

fossil fuel combustion |

Energy Category |

Net consumption (million Nm3) |

Low calorific value (GJ/million Nm3) |

|

Natural gas |

91.89 |

389.3 |

|

|

Purchased electricity |

Energy Category |

Quantity |

Unit |

|

Electricity |

7649.25 |

MWh |

The emission factors are all based on the default values specified in the Guidelines for Accounting Methods and Reporting of Greenhouse Gas Emissions from Other Non-ferrous Metal Smelting and Calendering Industries (Trial).

Table 3 Calculation coefficient of emission factor

|

Carbon content per unit calorific value (tC/GJ) |

carbon oxidation rate (%) |

||

|

fossil fuel combustion |

Natural gas |

0.0153 |

99 |

|

Purchased electricity |

Quantity |

Unit |

|

|

Electricity |

0.5257 |

tCO2/MWh |

- BOUNDARY EMISSION REPORT ENTERPRISE SUPPLEMENTARY DATA SHEET

By reviewing the plant's 2022 energy purchase settlement voucher to verify that the plant purchased 7649.25MWh of electricity and 918900 cubic meters of natural gas, then:

natural gas combustion direct emissions:

= 918900 Nm3× 389.3GJ/10,000 Nm3× 0.0153tC/GJ× 99% × 44/12tCO2/tC=1986.78 tCO2

Indirect emissions from purchased electricity = 7649.25MWh × 0.5257tCO2/MWh=4021.21tCO2

Table 4 Calculation of GHG emissions by reporting entities in 2021

|

Variety |

Data source |

Unit |

Numerical |

CO2Emissions (t) |

|

Natural gas |

□ Instrument metering □ Inventory records ■ Settlement voucher □ Other___ |

104m3 |

91.89 |

1986.78 |

|

Electricity |

□ Instrument metering ■ Settlement voucher □ Summary account □ Other___ |

MWh |

7649.25 |

4021.21 |

|

Summary |

6007.99 |

|||

- Other situations that wish to be explained

The plant does not produce greenhouse gases in the production process, the main sources of greenhouse gases in the plant are the use of electricity and natural gas, the plant's emission factors are all default values, the plant's activity level data are derived from monthly energy consumption settlement vouchers, and the plant has no carbon dioxide recovered and sold in the form of products.

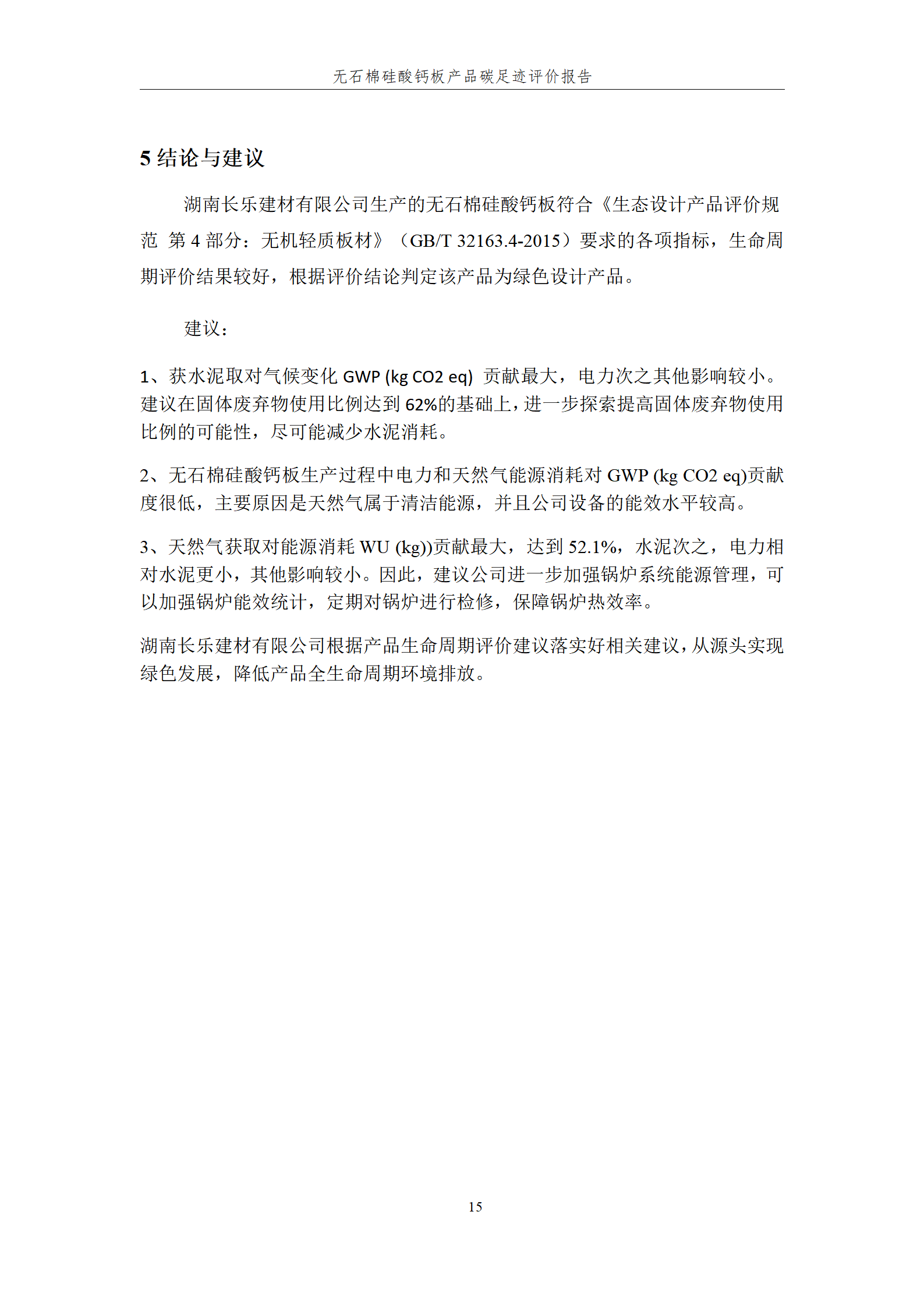

- Conclusions and recommendations

According to the greenhouse gas accounting report, outsourced electricity contributes the most to climate change GWP (kg CO2 eq), followed by natural gas:

1, do a good job of the company's equipment energy saving work, timely search new upgrade existing equipment;

2. Strengthen the company's management and energy conservation work to reduce unnecessary energy waste;

3. Optimize the company's structural energy-saving work and increase the proportion of renewable energy;

4. Upgrade the company's technical energy-saving work and adopt high-efficiency energy-saving technical solutions;

- Statement of Authenticity

This report is true and reliable. If the information in the report is inconsistent with the actual situation, the enterprise will bear the corresponding legal responsibility.

Legal person (signature):

Year Month Day

Related News

Contact Information

CONTACT US

Address: 306 Yingwu Road, Xiangtan County, Xiangtan City, Hunan Province

Mobile : 86-19083204228

86-15273259520

WeChat Public Number

Telephone

86-0731-52836228

Follow Us

Official

Official Account

- TOP